Overly Door Co.

The Tiger FRP series is seamless and manufactured with all non-organic materials and contains a non-porous surface. Its core consists of a 4-millimeter cell, polypropylene honeycomb surrounded by a rigid tubular FRP subframe. The skins for the door begin with the application of an in-mold 25-30-mil gel coat. A chopped-strand glass fiber mat then is applied to form the connective tissue, followed by a muscular bi-axial glass fiber that strengthens the door skins. The composite skins are simultaneously fused onto both faces and all edges of the door, forming a bond that fully integrates the components. Each unit is finished with a formulated multi-component polyurethane industrial chemical coating.

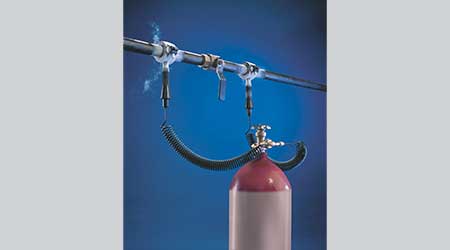

General Pipe Cleaners: Cold-Shot Pipe Freezing Kit

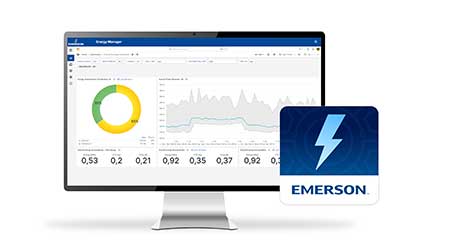

General Pipe Cleaners: Cold-Shot Pipe Freezing Kit Emerson: Energy Manager

Emerson: Energy Manager DMF Lighting: M Series Commercial Expansion

DMF Lighting: M Series Commercial Expansion Sherwin Williams: Accelera One

Sherwin Williams: Accelera One Shaw Contract: Montage

Shaw Contract: Montage