Maximum energy efficiency is the cornerstone of a long and growing list of building certification initiatives such as LEED, Green Globes, Zero Energy Buildings, Living Building Challenge, and Energy Star for Buildings.

And variable frequency drives (VFDs) are a key tool in achieving this energy efficiency. By allowing motors to run at less than full speed, VFDs match HVAC system capacity to changing heating/cooling loads, dramatically reducing energy costs. But VFDs can damage the bearings of motors they control – often in as little as 3 months! To ensure the reliability of VFD-driven HVAC motors and lock in energy savings, proven long-term bearing protection is essential.

Introduction

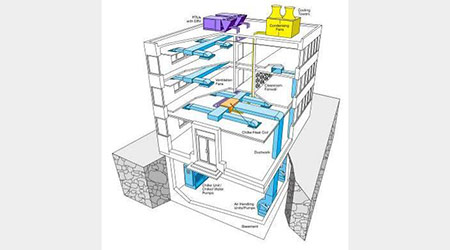

To reduce energy consumption, facility managers are installing VFDs (or inverters) in heating, ventilation, and air conditioning (HVAC) systems. Many HVAC fans and pumps run continuously, but often at reduced loads. Because the energy consumption of such devices correlates to their flow rate cubed, the motors that drive them will use less power if controlled by a VFD. In fact, reducing a fan’s speed by half cuts the horsepower needed to run it by a factor of eight. In light of this, throttling mechanisms that restrict the work of motors seem old-fashioned and wasteful. By allowing motors to run at less than full speed, VFDs yield energy savings of 30% or more. But VFDs also induce shaft currents that can damage bearings and shorten motor life, and resulting repair costs can wipe out any savings from their use. To make HVAC systems truly reliable as well as energy-efficient, proven long-term bearing protection is needed.

VFD-induced currents destroy bearings, kill motors

For years the true cause of VFD-induced bearing failure was often misdiagnosed. High peak voltages, fast voltage rise times, non-sinusoidal shaft currents, and parasitic capacitance associated with typical pulse-width-modulated VFDs lead to the cumulative erosion of bearings. Today, VFD-induced electrical bearing damage is the most common cause of bearing failure in VFD-controlled AC motors.

Without mitigation, voltages repeatedly build up on the motor shaft, then discharge in short bursts along the path of least resistance, which all too often runs through the motor’s bearings. The discharge rate tends to increase with carrier frequency.

Continued discharges result in the pitting [Figure 1] of the balls and race walls through electrical discharge machining (EDM). Concentrated pitting at regular intervals along the race wall can cause washboard-like ridges called fluting [Figure 2], a source of vibration and noise that can reverberate through ductwork. By the time such damage can be heard, bearing failure is often imminent.

NEMA standards call for shaft grounding

National Electrical Manufacturers Association (NEMA) standards highlight the need for extra bearing protection for VFD-driven motors. These standards also suggest best practices for protecting VFD-driven motors that include the installation of shaft grounding brushes to safely channel harmful voltages away from bearings to ground.

Ironically, some products designed to protect bearings from electrical damage, such as conventional spring-loaded grounding brushes, require extensive maintenance themselves. Others, such as ceramic bearings, can shift damage to connected equipment. Many so-called “inverter-duty” motors offer beefed-up winding insulation, which does nothing to guard against bearing damage. To be truly ready for use with VFDs, these motors also need bearing protection.

Circumferential conductive microfiber shaft grounding rings

Installed around a motor shaft, maintenance-free AEGIS Shaft Grounding Rings provide a very-low-impedance path from shaft to ground, bypassing motor bearings.

These rings can be quickly and easily retrofitted onto any NEMA or IEC motor regardless of shaft size, horsepower, or end-bell protrusion using conductive epoxy or a Universal Mounting Kit. The conductive microfibers that line the ring’s entire inner circumference in two rows, completely surround the motor shaft, boosting the ring’s electron transfer rate. The rings require no maintenance and last for the life of the motor, regardless of rpm. When installed on VFD-controlled motors, they qualify as sustainable technology under the Federal Energy Management Program.

Shaft grounding proven effective on rooftop unit

These rings recently proved effective in protecting motors of a packaged rooftop HVAC unit typical of those installed on commercial buildings. The unit’s VFD-controlled motor runs a belt-driven fan. Technicians from Electro Static Technology (the manufacturer of AEGIS Rings) took voltage readings — both before and after installing the ring on the motor’s shaft — using a voltage probe and a portable oscilloscope.

In a continuous 60-µsec trace with the motor running at 3,600 rpm (80Hz output), discharges from the shaft were 44.8 volts peak-to-peak, high enough to cause pitting of the motor’s bearings. After an AEGIS Shaft Grounding Ring was installed, follow-up readings at 3,600 rpm showed discharges of only 3.76 volts peak-to-peak, well below levels that damage bearings.

Another success with hospital air handling unit

Another recent test took place at a Chicago community hospital. Reliable heating and cooling are important for patient comfort, and continuous ventilation is vital in promoting sterility and limiting infections, especially in operating rooms, intensive-care units, quarantine areas, and laboratories.

A 3-phase TEFC motor, controlled by a 480-volt VFD (60 Hz output), runs a fan in an air handling unit for several operating rooms. Using a voltage probe and oscilloscope, EST technicians confirmed that VFD-induced voltages were building up on the motor shaft and discharging through the bearings at spikes of 11.4 volts peak-to-peak – high enough to cause pitting.

Follow-up readings after the AEGIS Ring was installed showed the ring had reduced shaft voltage discharges by 83 percent.

Because the ring was effectively channeling harmful shaft currents away from bearings to ground, the new peak-to-peak reading was 1.92 volts, too low to damage bearings.

Conclusion

Operations and maintenance costs can account for 60-80 percent of a facility’s life-cycle costs. When HVAC equipment does not have to be repaired or replaced as often, this percentage drops significantly.

VFDs hold the promise of sizable energy savings, but without effective, long-term bearing protection these savings can be wiped out by high maintenance costs. By diverting bearing currents safely to ground, AEGIS Rings extend motor life and ensure the reliable, long-term operation of VFD-driven systems, locking in energy savings and making these systems sustainable.

Adam Willwerth is Development Manager for Electro Static Technology.

Mature Dry Surface Biofilm Presents a Problem for Candida Auris

Mature Dry Surface Biofilm Presents a Problem for Candida Auris Sutter Health's Arden Care Center Officially Opens

Sutter Health's Arden Care Center Officially Opens Insight Hospital and Medical Center Falls to Data Breach

Insight Hospital and Medical Center Falls to Data Breach The High Cost of Healthcare Violence

The High Cost of Healthcare Violence EVS Teams Can Improve Patient Experience in Emergency Departments

EVS Teams Can Improve Patient Experience in Emergency Departments