The University of Utah (U of U) Health Sciences Campus houses nearly four million square feet of critical patient care, laboratory and educational space. In 2017, the U of U broke ground on several new cutting-edge buildings – totaling nearly 800,000 square feet – transforming the campus. During expansion planning, the university realized that their existing chilled water plant did not have the capacity to meet the loads of these new buildings scheduled to come online.

The U of U Planning, Design and Construction (PDC) team studied how best to meet this new cooling load – either by adding new chillers at a cost of nearly $40 million, or by significantly decreasing the cooling load in existing buildings. The team determined that they could reduce the load in the existing buildings for less than $25 million, which would also result in ongoing energy savings.

The choice was clear, and the university set out to design, build and execute these energy-savings measures. The PDC approached this project with the dual goal of reducing the load on the chilled water plant by at least 2,000 tons and saving enough energy in the process to pay back the capital used to fund the project within 10 years.

Accomplishing energy savings

When the project kicked off in 2017, the university partnered with our firm to conduct an investment-grade audit across 24 buildings on the Health Sciences Campus. This audit revealed a list of facility improvement measures focused on reducing chilled water demand and consumption. During 2018 and 2019, the project partners designed, installed, implemented and commissioned these energy efficiency measures across the Health Sciences Campus, including:

• Chiller plant modifications to improve efficiency, including:

• Replacing chilled water control valves to stabilize flow of water to more effectively control the flow during low load periods.

• Installation of precision controlled, pressure independent control valves on chilled water coils to provide chilled water at the appropriate temperature.

• Eliminated flat-plate heat exchanges from buildings connected to the plant.

• Air handling unit improvements, including:

• Adding N+1 redundancy to critical spaces through fan arrays

• Installing indirect evaporative cooling coils and new cooling towers and direct evaporative cooling systems to take advantage of evaporative cooling.

• Installing precision air control valves to correct over-ventilating

• New centralized boiler plant

• Active Energy Management (AEM) program: To provide thorough, real-time data on campus energy consumption in a dashboard format

• Transition to Sustainable Operations (TSO) services: To help U of U’s operations staff take ownership and ensure their energy efficiency is persistent

According to our projections, these energy efficiency measures will save the university more than $3 million annually in energy and operational costs.

Project results

Because of the critical nature of the medical buildings on the campus, failure to reduce the loads of the plant before the new buildings came online was not an option. To demonstrate our confidence in our recommendations, we committed to refund one third of our fee if the chilled water plant did not have the capacity to meet the loads of the new buildings during the summer of 2019.

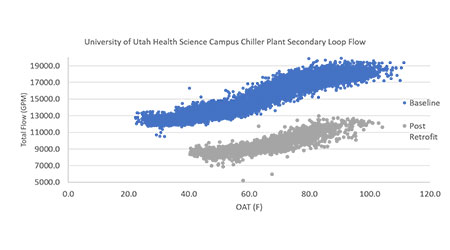

As these new buildings came online and the weather warmed up, the data showed that the energy efficiency project dramatically reduced chilled water flow while maintaining excellent performance in the buildings themselves.

Below is a chart that shows the pre-retrofit and post-retrofit flow at the chilled water plant. At nearly all outdoor air conditions, the plant is pumping nearly 6,000 gallons per minute (GPM) less than before the project commenced, while still cooling all existing and new buildings.

Continued energy savings

TSO and AEM are both critical to the long-term success of this project. The project team designed AEM and TSO strategies to help the U of U maintain and track the performance of the building systems. We are also integrating asset management, warranty management, training and proactive maintenance into the university’s operations.

For example, an AEM monitoring dashboard tracks building assets and maintenance items, offering visibility (and thus effectiveness) to building operations staff. Ultimately, this effort will establish a new benchmark on the university’s campus, enhancing outcomes for all other future facility improvements.

If the buildings are not meeting key performance indicators, AEM data will help the U of U identify and address potential operational issues at an early stage. Because of the 10-year payback requirement of the project, we will also be tracking ongoing project dollar savings as a key performance indicator.

TSO services ensure that maintenance staff hit the ground running with detailed asset data and management protocols. What’s more, TSO is ensuring staff capture warranty repairs and that they have the necessary information at their fingertips – allowing energy savings to remain consistent and persistent.

DJ Hubler, project director, and Erick Allen, account executive, work in McKinstry’s Mountain Region.

Healthcare and Resilience: A Pledge for Change

Healthcare and Resilience: A Pledge for Change Texas Health Resources Announces New Hospital for North McKinney

Texas Health Resources Announces New Hospital for North McKinney Cedar Point Health Falls Victim to Data Breach

Cedar Point Health Falls Victim to Data Breach Fire Protection in Healthcare: Why Active and Passive Systems Must Work as One

Fire Protection in Healthcare: Why Active and Passive Systems Must Work as One Cleveland Clinic Hits Key Milestones for Palm Beach County Expansion

Cleveland Clinic Hits Key Milestones for Palm Beach County Expansion